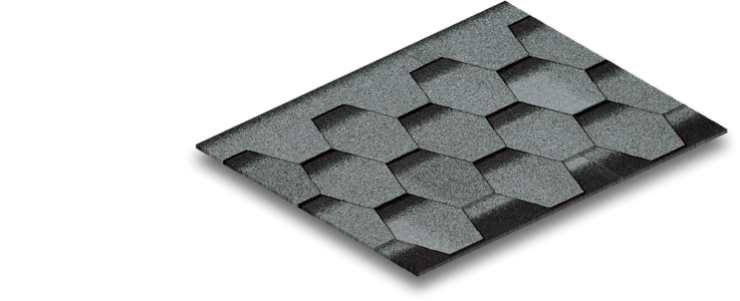

BTM Shingle Yakut

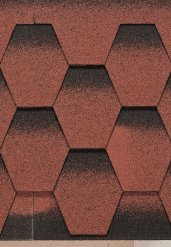

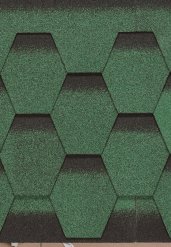

BTM Shingle Yakut a self-adhesive fibreglass-reinforced roof covering and waterproofing membrane made of oxidated bitumen, which is coated with sand on the lower surface and by coloured mineral granules on the upper surface.

BTM Shingle Yakut a self-adhesive fibreglass-reinforced roof covering and waterproofing membrane made of oxidated bitumen, which is coated with sand on the lower surface and by coloured mineral granules on the upper surface.

For roof covering and waterproofing purposes on sloping roofs, on sloping pergolas.

Dimensions: 32 cm width, 100 cm length

In general,shingle roof covering is used on roofs with more than 20% pitch.

During application of BTM Shingle Yakut, shingle plate should be removed by peeling of the removable plastic folio protecting the self-adhesive part. Thus, adhesive part shall ensure complete adhesion on the plates of the lower layer.

Please see the Shingle Application Guide or the application information on the packaging.

BTM Shingle Yakut is launched into the market in packs. A pack contains 21 sheets, and 21 sheets are good to cover 2,94 m2 of finished surface.

Packs must be stored in roofed-over spaces. They must be stored not more than three packs one on top of the other and out of the sunlight

Shingle packages should be protected from low & high temperatures and moisture before use.

The roofing materials (OSB, water plywood) to be Shingle covered should be dry.

OSB panel end joints must be staggered and a minumum of 3 mm of expansion gap must be left in all edges, in order to prevent shingle layer from substrate movement. BTM A.S. can not be held responsible for any damages on shingled roofs caused by inappropriately constructed decks.

An appropriate ventilation system should be provided in order not let roof temperature increase.

An appropriate ventilation system should be provided in order to prevent premature failure of the roofing including blistering, buckling of the roofing shingles due to deck movement. If implemented correctly, proper ventilation methods can help ensure the maximum service life of roof assembly materials. It is recommended a minimum of at least 1 square metre of attic ventilation (both intake and exhaust) for every 300 square metres of attic space. This amount should be divided equally between intake and exhaust ventilation to insure proper air flow through the attic. Two types of exhaust vents are available; one with cap, other without cap. One exhaust vent for every 10 square metre of attic space to be installed near the ridge, for a proper ventilation. Also, proper intake space along eaves should be provided with bird and insect netting. BTM A.S. can not be held responsible for any damages on shingled roofs caused by inappropriate or no attic ventilation.